McCourtney Hall, formerly called the Multidisciplinary Research Building, is the first dedicated research building to be constructed at the University of Notre Dame’s East Campus Research Complex. The three-story building offers more than 200,000 square feet, of which approximately half is allocated to open laboratory and team spaces. Construction was completed on schedule in late 2016.

Peter Kilpatrick, Dean of the College of Engineering at Notre Dame, summarizes the building’s purpose succinctly:

The state-of-the art facilities in McCourtney Hall will enable collaborative research among a large number of faculty and students working in the areas of molecular science and engineering. Within the Department of Chemical and Biomolecular Engineering, researchers will engage in work dedicated to several critical areas including clean water, sustainable resource and energy utilization, medical diagnostics and cancer therapies.

The nature of the research that will be undertaken in this groundbreaking facility means that the architect and engineers at BSA LifeStructures needed solid advice to guarantee that the laboratories’ planned exhausts and air intakes would meet safety standards, both for building occupants and for their surrounding neighbors.

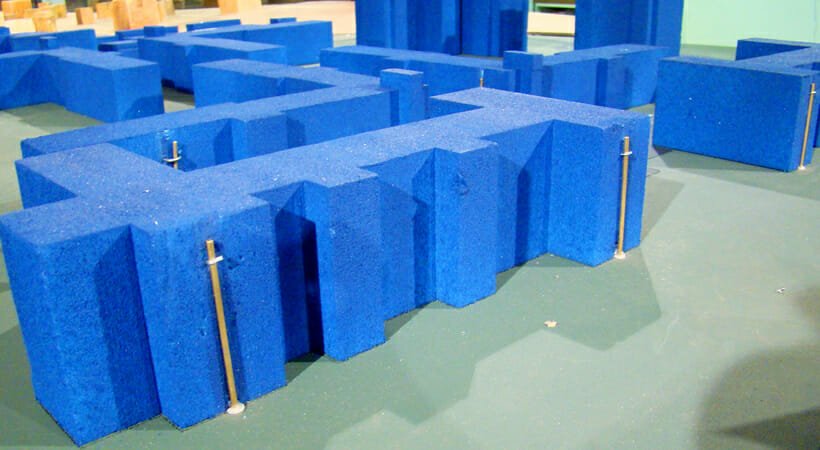

To meet the needs of BSA and the University of Notre Dame, CPP’s air quality team designed and built a 1:240 scale model of the proposed building, including all major buildings and structures within 1,360 feet (415 meters). We instrumented the model with exhaust sources located at the building’s proposed exhaust locations, and with receptors located at sensitive locations on and near the building. We also included receptors at nearby buildings, including future dormitories and other buildings that have been planned but which have not yet been built.

We then tested the model in our atmospheric boundary layer wind tunnel to assess air quality performance of the various relevant exhausts. Releasing tracer gas from exhaust sources and measuring the concentrations of that gas at the various receptor locations produced quantitative data that we used to provide specific recommendations to the design team. The modular nature of our model, along with sophisticated data processing techniques, allowed us to evaluate a range of design options and operational scenarios, including

- Several candidate air intake configurations along the rooftop and in the courtyard.

- Different fan selections, including variable air volume (VAV) options.

- Three possible locations for anemometers to measure local wind conditions.

- A diesel generator to be used in emergencies.

- Idling diesel vehicles.

Based on the results of our assessment, CPP recommended a specific anemometer location, height, and model to measure the wind speed and wind direction at the building itself. Data from the anemometer can be used as an input to the Building Automation System to allow for reduced exhaust volume flow rates under most wind conditions (as measured by the anemometer), saving the university both energy and money.

Our recommendations go beyond the building code and deliver insights and analyses that just can’t be had any other way. CPP is proud to have been able to partner with BSA LifeStructures and the University of Notre Dame to ensure that McCourtney Hall remains safe, comfortable, and efficient.