Wind Tunnel Testing to Aid Compliance

In 2012, the EPA’s National Ambient Air Quality Standards (NAAQS) became more stringent. Now, initial models are more likely to show that your facility exceeds the significant impact levels (SILs), which will mandate a detailed air quality impact assessment. AERMOD modeling is also more likely to show non-compliance in many situations. But is this really the case?

Wind tunnel testing provides accurate concentration predictions at a lower cost than many mitigation measures or air quality impact assessments. Using industrial wind tunnel modeling in your assessment can:

- Show that predicted impacts are below the SIL

- Demonstrate reduced impacts on air quality of your project on PSD increments and/or NAAQS

- Minimize required emission control

- Optimize your stack height

Equivalent Building Dimensions (EBD) for Better Inputs to AERMOD

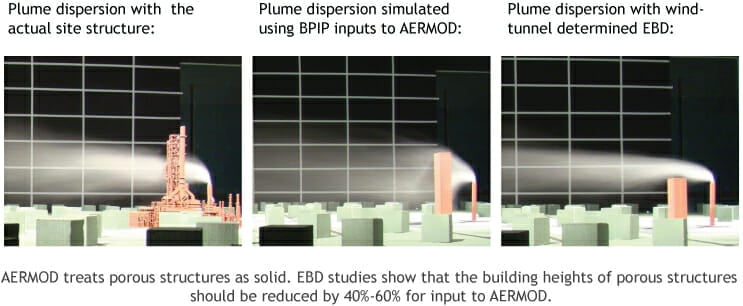

In many cases, AERMOD will over-predict concentrations. This is because BPIP, the standard tool for determining building dimension inputs, handles many situations poorly. For example, in some cases BPIP will:

- Merge nearby buildings into a single building

- Ignore or misrepresent lattice structures

- Mishandle buildings with a low, large footprint or complex geometry

- Ignore the effects of terrain

CPP’s Equivalent Building Dimension (EBD) procedure avoids these mistakes by starting with an accurate model of the actual site. By testing the scale-model plume behavior, CPP experts can identify the right AERMOD-ready dimensions that match the scale-model tests. The EBD method provides more accurate, and often lower, concentration estimates.

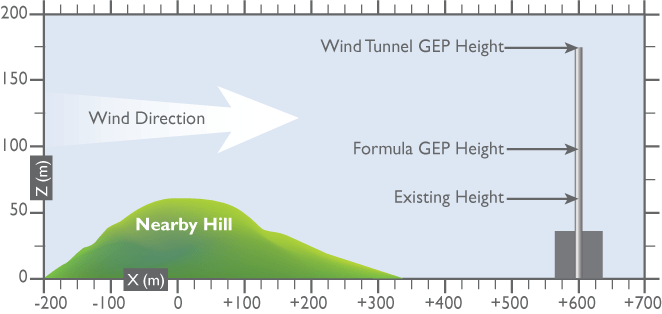

Good Engineering Practice (GEP) Stack Height

Many believe that GEP stack height is limited to 65m or 2.5 times the height of the building. Not true. Depending on the surroundings and the details of the project, wind tunnel testing can justify heights above the formula or, in some cases, show that the higher stack is not actually needed for compliance.